Continously Variable Transmissions

Popular Science August 1992, page 30

Automotive Newsfront

Gearing For the Infinite

by Stuart Brown

IVT Invented by Paul Pires

Developed by Epilogics Inc.

Los Gatos, Ca

August 2, 1994

US Patent 5334115 granted to Inventor Pires, Paul B.

Assignee: Epilogics

The transmissions in all our vehicles, automatics and manuals alike, are also known to be significantly inefficient and solutions exist in alternatives, including known infinitely variable transmissions.

- able to handle large amounts of torque

- the gears are never disengaged

- no friction clutches with low torque and high heat

- no fluid couplings to leak or require pressure

| Other References: Fitz, Frank A., “The Epilogics infinitely variable transmission,” Automotive Technology, pp. 215-220, 1992. ;, pp. 215-220, 1992. Puttre, Michael, “Continuously Variable Transmissions,” Mechanical Engineering, pp. 64-67, 1991. ;, pp. 64-67, 1991. Fitz, Frank A. and Paul B. Pires, “A Geared Infinitely Variable Transmission for Automotive Applications,” Society of Automotive Engineers paper presented at the SAE International Congress and Exposition, pp. 1-7, 1991. Fitz, Frank A. and Paul B. Pires, “A High Torque, High Efficiency CVT for Electric Vehicles,” Electric Vehicle Design and Development SP-862 paper for Society of Automotive Engineers, ISBN: 1-56091-126-3, pp. 111-116, 1991. |

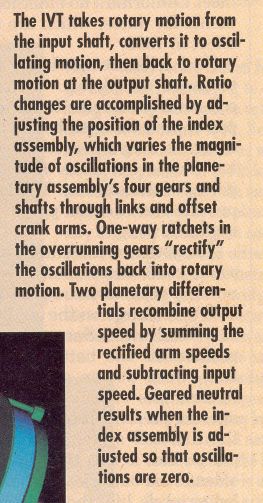

Picture a housing full of gears with shafts emerging at both ends. Imagine twisting the input shaft with one hand while grasping the output shaft with the other hand. Now ponder this mystery: Though all the gears are meshed – and there are no friction clutches or fluid couplings in the gear train – the output shaft stays stationary, and no torque is felt on the output side.

So where on earth did the motion go? Even a master clockkmaker could get a little crazy bending his mind around the elusive interplay of movement, inside the purely mechanical, infinitely variable (IVT) transmission developed by Epilogics Inc. in Los Gatos, Calif.”

The IVT is the invention of Paul Pires, a soft-spoken mechanical designer who puzzled the complex mechanism out in his head before building a model of it – and when he did build it, it worked! Pires’s background is in designing equipment used in electronics manufacturing, which may account for his preference for thinking about mechanisms and describing them in the lingo of circuitry; “Dealing with things on a symbolic level helps me come up with the concept, then I backtrack through the hardware,” he explains. “I think of an overrunning clutch as a diode, for instance.”

In characteristically electronic metaphors, Pires offers this description of the IVT’s workings: “We take a DC signal, turn it into an AC signal, rectify it, and sum it – but we do it mechanically.”

Pires, works out refinements to the IVT concept using a kinematic analysis computer program introduced recently by Rasna Corp. in nearby Sari Jose, Calif. Developed to help mechanical designers model the inter-relationships between moving parts. The software predicts collisions and problems of fit without the heartbreak of destroying actuual prototype components. The accompanying [color] illustrations were generated on the Rasna system.

The ultimate dream of these transmission developers is licensing their designs to, auto makers for production by the millions. Cars with engines optimized for steady-state operation at their most efficient speed could have fuel consumption and exhaust emissions reduced by as much as 30 percent, according to some estimates, But new devices like the IVT run up against the fact that auto makers already have transmissions they are happy with. The huge expense and risk of tooling up for a radically different design is unappealing to them in times of inexpensive fuel and relaxed government regulation.

As a result, it’s possible that the first IVT-geared car to hit the pavement will do so at supra-legal speeds. An engineer with a major team active in several classes of motor racing (who insisted on anonymity) says they have concluded from computer simulations that a “shiftless” race car could turn lap times several seconds quicker than conventionnal machines, providing the IVT doesn’t add appreciable weight – and race rules permit its use.

Among the beltless transmission’s characteristics are its ability to handle large amounts of torque – a severe shortcoming of most continnuously variable transmissions (CVTs) – and its lack of wear-prone sliding parts or fluid couplings that waste energy in the form of heat. It can shift steplessly from a “geared neutral” up to an input-to-output speed ratio of five to one.

Together, these features have caught the attention of manufacturers of machinery ranging from truck transmissions to electricity generators. They see the infinitely variable transmission as a potential route to sizable fuel efficiency and performance improvements.

One of the first projects Epilogics tackled was building a large IVT into a heavy diesel tractor, which it demonstrated to a group of truck engineers. At present, though, it appears that the first commercial applications of the IVT may be relatively miniature in scale, according to Wayne Higashi, president of Epilogics. He says a maker of fan clutches for truck engines is showing customers a small prototype IVT that keeps the cooling fan running at a constant speed for better temperaature control.

Another component maker, C.E Niehoff & Co. of Evanston, Ill., wants to apply an IVT to the heavy-duty alternators it builds for transit buses and military vehicles. Currently, such vehicles require very large alternators in order to power accessories, such as air conditioners and electronic equipment, when the engine idling. Niehoff is using the IVT to drive a much smaller alternator at a constant speed to save engine fuel and keep the electrical components at a stable temperature for ” longer life. “I happen to believe in this set of weird gears,” says George Buhrfeind, the company’s president.

Detroit Diesel Corp. has surveyed the continuously variable transmission field for years, found fatal drawbacks to existing designs, and now would like to test an IVT. “We want to be able to get more power, when it’s needed, by increasing the speed of our diesel engines used in constant-rpm applications like emergency generator sets for hospitals. A smaller engine can do the job under varying load conditions, if you can somehow keep its output speed constant,” says Rob Sisk, vice president of power systems.

There were plans to use Pires IVT in racecars, if race rules would permit. There were plans for use in generators and alternators; even the transmissions of Detroit Diesel Corp. trucks.

One of its characteristics is its ability to handle large amounts of torque, a severe shortcoming of most IVT’s with their belts or wear prone sliding parts or fluid couplings that waste energy in the form of heat.

SAE International

A Geared Infinitely Variable Transmission for Automotive Applications

Document Number: 910407

Date Published: February 1991

Author(s):

Frank A. Fitz – Epilogics, Inc.

Paul B. Pires – Epilogics, Inc.

Abstract:

Epilogics, a young engineering firm in Los Gatos, CA, has developed the first fully-geared, high torque, high efficiency, infinitely variable transmission (IVT) suitable for automotive applications. To prove its torque capacity, Epilogics demonstrated a prototype of its patented transmission concept in a Class VII diesel truck in June 1989. In addition to being ideally suited as a transmission for motor vehicle drivetrains, the IVT can provide a means to efficiently and flexibly drive engine accessories independently of engine speed. Products have already been designed or built to drive alternators at a constant speed (irrespective of engine/vehicle speed) and to control cooling fan speeds independently of engine/vehicle speed. Outside of automotive applications, experimental designs of automatically adjusting manual sailboat winches and continuously variable bicycle transmissions have been implemented. Under normal operating conditions, the efficiency of the Epilogics transmission exceeds 90% as derived mathematically and corroborated experimentally. The device does not rely on traction to transmit torque and can therefore match the torque capacity of any typical gear drive. The size, weight, and cost of the device closely approximates that of a four-speed manual transmission.

The expectation is that fuel consumption can be reduced by up to 30%. As such, the IVT may only buy a little time since auto makers seem to keep building larger and heavier vehicles every year and an IVT might just open their door to putting larger engines in the cars to attract everyone who wants more power. Still, the Mini Cooper offers a crude one today and if it saves gas, some of us will “go for it”. We know that this one has been bought by Eaton corp. but have no further information yet.

The new era of electric powered vehicles may change everything. The Epilogics IVT could enable greater acceleration and extend the top speed of electric powered vehicles.

Some Mini Coopers use a CVT today.

THE MINI COOPER: A 5-speed manual transmission with overdrive is standard, and a variable speed automatic transmission is optional.

The Mini Cooper’s Continuosly Variable transmission uses a fixed-length steel drive belt to connect two double cone-shaped belt pulleys which transmit the drive output from the engine, essentially offering infinitely variable transmission ratios. Electronically controlled coupling does not transmit the full power until an engine speed of 2,000 rpm. Although the continuously variable transmission is still heavier than manual transmission, it is lighter than a conventional automatic transmission. When the driver presses the accelerator, the action is transmitted to the Powertrain Controller (a Siemens EMS 2000 control unit), which then determines the ideal amount of fuel to supply to the engine. With more powerful acceleration, the system can determine the best fuel feed for maximum performance and minimum emissions.

The Base is equipped with a standard 1.6-liter, I4, 115-horsepower engine that achieves 28-mpg in the city and 37-mpg on the highway.

The S is equipped with a standard 1.6-liter, I4, 163-horsepower, supercharged engine that achieves 24-mpg in the city and 33-mpg on the highway. A 6-speed manual transmission is standard.

The Honda Insight has an optional CVT.

( Unfortunately, the gas mileage with their IVT is not significantly different)

Hi, my name is Graeme John Eddington from Perth, Western Australia. I have invented an IVT …

Sorry.

Take a look at Australian Innovation Patent No. 2012100212 – This Patent is available to anyone who wants to use it. . . .

Graeme John Eddington

Inventor/designer of s-trans2010 -at- hotmail.com

Smart-S-trans, Perth Western Australia

there is nothing to see. A website-page with diagrams, blueprints, photographs, instructions, and/or video would be helpful.

Patents are full of IVTs using sinusoidally varying inertial forces which are then rectified by means of ratchets, sprag clutches and one way spring clutches. I fact back in the 20s there were several vehicles testing them (one of them was the “Spontan” transmission) with ultimate failure, as these discontinuous devices cannot withstand the numbet of stress cycles required. It’s a waste of time and money.

I have been considering purchasing a V8 inboard powered boat. The downside is weight and (unknown) fuel economy. The salesman mentioned that if I put a coarser prop on it I would get way better economy but no acceleration. After pondering this I looked up CVTs on the net and found your site. Kiwis (NZers) are well known “do it yourselfers” If a suitable IVT were available and an article appeared in a NZ boat magazine showing the economy gains, there would soon be hundreds of kiwis shifting their boat motor forward a bit to accomodate it. As the population of the USA is vastly bigger than ours, perhaps this is a “back door” way of getting into the automotive market. I’m sure it would become a popular modification. Please pass this suggestion on to the inventor. Thanks for the article, Ian.

I’m the one that needs several IVT transmissions but I forgot to leave my email at chrisonic53 *[at]* gmail.com

I have a big shop if I need to build them.

Thx,

Chris

806-789-7900

If you have a shop and can build one, that is great. As stated above, Eaton has the license on it. I hope the 2 drawings here are enough to replicate it for yourself.

Hi,

I need an IVT for my ’96 Dodge Cummins 4×4. How much & when can I get it? I might need several more.

Thx,

Chris

806-789-7900

Is this the transmission John Deere is using?

if you have seen the youTube video of the JD IVT, one cluster of parts looks like Paul Pieres, Epilogincs, design, but another green-highlighted pard looks like a traditional belt design.

No one is talking.