updated 08-02-2014

from Tesla’s Flying Machine, page 1

Tesla’s Flying Machine

Page 2

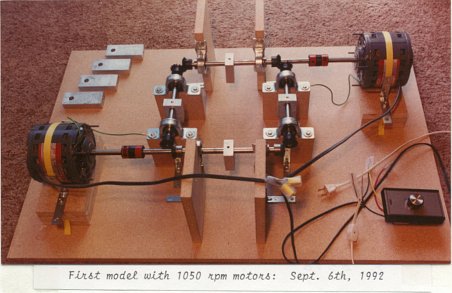

“Tesla’s Flying Stove”

“Not the airplane, the flying machine,” responded Dr. Tesla.

A few weeks later, I traded these motors for 10,000 rpm 1/5hp motors.

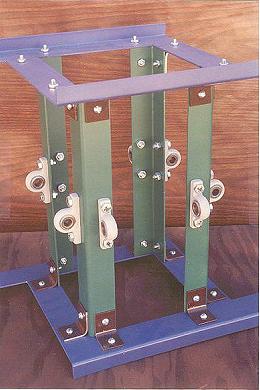

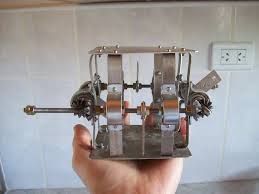

Second Tesla Space Drive Design

Since nothing is said about weight being an issue, my second

(all steel) frame was built to be rigid, not light-weight.

it was right after this that I figured out the speed

requirement and the variables that affect it

Third model, with 10,000 rpm ele. motors

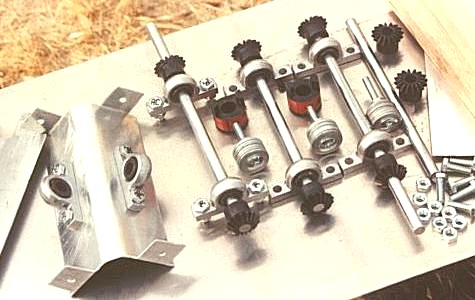

The only expensive parts are the motors, (aluminum) pillow blocks, and mitre gears.

The pillow blocks, and mitre gears, combined, totalled $138.44. About a 2 foot square sheet of aluminum was less than $10. The shafts are also aluminum and cheap.

The shafts and pillow blocks are also, now, aluminum alloy. This model was fine but, the frame was just a little flimsy.

Note: I used the red/orange (Lovejoy) jaw couplings because they were a cheap easy way to attach weights on a shaft. I just replaced the set-screws with bolts. For a good close-up, click on the photo above (the 3 photos) to see an enlargement.

Experimenting out in the back yard, 1993

here I and a friend discovered the frame flexed a little

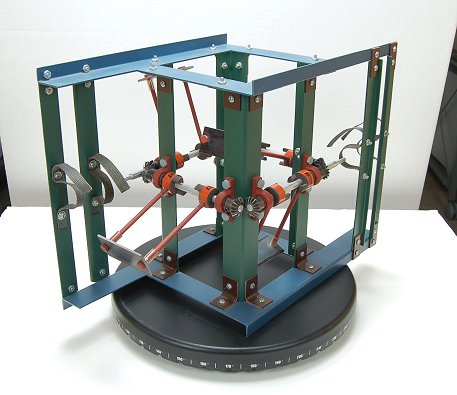

Final design: January 1994

using .090 inch aircraft aluminum ($9)

and 2 22,000rpm air motors ($50)

the frame is rigid and the motors are very light weight

I made the frame taller to accommodate longer arms and, slower speed requirements but, that was not necessary. However, there is an increased strength and reduced stress benefit to the double arms.

photographed on Fri., March 24th, 2006

Oct. 20th, 2007:

A few weeks ago +/- I tried it without any crossbars but, the weight and inertia were still too much for the motors. we got maybe 200 rpm but, we need maybe 600 to 800 rpm? I think the air pump where I am trying it, is not as strong as the one I used in Phoenix.

Nov. 2007:

I bought 2.5″ bolts and 1.5″ bolts so I have 2 more options. If the 2.5″ does not reduce the weight and inertia enough to enable the motors to get up some significant speed, I can try the 1.5″ bolts.

Cutting the length, and weight, in about half (from 4.75″ to 2.5″ bolts) reduces our net radius from about .1″ to about .025″ and our needed speed from about 600+ rpm to about 1200 rpm. Although it was an improvement, It just was not enough improvement and we switched to the 1.5 inchers. (see “December 2007” photo below) We started it up and the speed finally seemed significantly improved. A mechanic said it looked like it was going about 5 or 6,000 rpm. Great! Finally! Still, nothing more happened and we turned it off.

(we have no way of confirming how fast it was going – I think maybe only 1 or 2,000 rpm)

December 2007

Afterwards, I realized several potential problems. (1. The force may have been exerted downward instead of up (we need to try turning it upside down) and, (2. the 2 air hoses were adding weight to the system, holding it down. We need to prop the hoses up so that they do not add weight to the system.

Jan. 30th 2008:

We tried it again, right side up and upside down. We held up the 2 air hoses. But, no movement, no lift. It may be that we need 3-4000 rpm but are only getting 1 or 2000.

Testing at an auto body shop, Jan 30th 2008

|

|

June 30th 2008

If we got several thousand rpm, enough(?), then, it didn’t work. If not, then either a further reduction in the mass and inertia of the rotating weights and / or a change to stronger motors is needed.

Hopefully, we can get a sufficient speed increase by further reducing the weights & inertia. If not that, then by getting the weight of the motors off the frame by using couplers to extend the 2 shafts out beyond the frame.

March, 2009

I started getting calls from a TV production co. in Calif. wanting to put my flying machine on a Discovery Channel special.

I stopped at the auto shop, told them about it. They told me that they have gotten a new, stronger, compressor. Now is the time to try again!

Saturday, March 21st, 2009

Saturday was a disappointment. The new compressor provided significantly more power than the old one. The speed was much improved, very impressive, “more than enough”. This time I do think it was up to 3 or 4000 rpm, if not more. However, the weather was bad, raining, and I only did half the test. Still, it did not move. There was plenty of speed in the rotating masses. So, either I had it upside down, 50-50 chance of that being true, since it is totally symmetrical, or there is some stumbling block, some criteria I have not thought of.

Wednesday, July 22nd, 2009, 9am

Tried it again. The speed, again, seemed enough. But, again, I can’t be sure, and it did not go up.

2011, Footnote:

A frame is cheap, a person can design and build one around motors they come up with, the smaller the better, perhaps. Smaller motors can generally run at higher speeds. Extension rods, longer rods, can be used to get the motors off the system, and that will reduce the total weight greatly.

Here is one Marcelo B. built. Glad to hear from him.

back to Tesla’s Flying Machine, page 1

Do the eccentrics as the drawing but change the shaft to fibre for isolation and the eccentrics to the best static plastic material it worked on static forces remmeber to use two different sorses for the drivers to prevent static discharge and remember it works on static change the main frame to a neutral material

Fanie Nel

Your using the wrong eccentrics! Tesla didn’t work with wood or weights. He worked using electromagnetic forces. This device would generate electromagnetic forces if you would use the right eccentrics…….

Would you like to sell me yours? Is this site glitchy to anyone else? Keeps booting me.

no problem that we know of. Try going through a proxy server (do a google search for free proxy servers and try one) and see if that gets around, stops, the problem.

We don’t have any Tesla Drives to sell. We recommend you build one smaller.

Think of the weights as wings, when the weight is thrown down it causes a slight lift of the frame. However when its thrown up it forces the frame back down. Now, spin the whole frame from the center and centrifugal force will amplify the outer stroke and numb or weaken the effect of the inner stroke. That seems like it would work to me, I wish I could afford to build one.

spinning does not change the fact that the up and down inertial forces are balanced. No one has any excuse to not experiment themselves. The materials are cheap.

Check out Inertial Propulsion http://www.youtube.com/watch?v=nIt661hfr9c

And do research on that

Tesla Man

If the materials are cheap, you should try it yourself. otherwise … there is a lot of experimenting with electromagnetic propulsion.

I noticed you attached the weights not in accordance with the actual plan. Difference being that weights opposite each other are exactly aligned. And are phases out 90 degrees of one another. Hope helps.

puru

Hello

I’ve been looking into inertia drive for a while and have built a few. The stove drive if you look at the plan, the Whole thing is meant to spin at a 1 to 1 ratio on a center shaft. This would make the weights stay out one side. I haven’t built it yet but have a go

Ross Richards

spinning an electrical coil will not generate an electric field but, you can try it.

…Just my 10 pence worth, but if you were to replace the weights with hollow plastic circular containers (think of the cheap concrete filled weight lifting gear) and fill with ferrofluid, you would be able to spin up to the maximum RPM (with no magnetic field you would essentially be spinning up a flywheel) and control the amount of eccentricity in the weight distribution using electromagnets. This would additionally allow you to tune the direction of force for each weight.

On the downside it could just heat up thefluid due to friction with the container sides – would make an interesting experiment though…

John Davies

Hi, just an idea? Have you ever thought about your counter weights spinning to be magnets? all with the north or south poles faceing the same way?, get those spinning then, also spin the entire box counter clock wise, like tesla drawing shows? also try spining your counter weight magnets the other way? Anyway I wonder if that would make some type of effect? kind of like the goerge green magnet motor?

magnets are for electro-magnetic propulsion. Do a google search on it. The Germans in WWII used it in their flying saucers and supposedly went to Mars with one. It is said that their trip took 8 months. This uses nuclear forces that are a thousand times more powerful.

In regards to Sid’s serious comment above: That is U.S. Patent 3,626,605. Using Bismuth as the dynamic and stationary sources. (vaguely unmentioned and secret therefore excluded from the patent). Bismuth has unusual gravitational properties.

If each dynamic weight was made of bismuth like pictured in the revolving secondary rotor in the patent above, this then could generate the stationary non-electromagnetic force, but correlated unknown forces focused in a Tesla Coil like spiral upward direction from the 4 rotating bismuth weights.

Then apply the voltage potential to current correlation equation from a tesla coil , but in regards to the newly generated (and proven back in the day until classified) non-electromagnetic force spiral algebraic summation.

And you should be able to blast off in a amplified gravity (b) wave bending of space and time , as planetary G forces are very weak comparison.

As a plus, power the motors with Aethic Cosmic Rays (Radiant Energy) from U.S. Patents (on Tesla Radiant Energy pages).

Neither Sid nor I said anything about Bismuth or patent 3,626,605.

However, the military is always secretly ahead of all of us: I have read about element 115 (an alien fuel source) reverse engineered and used in “flying disks” at the military site S4 near Groom Lake. Unoficially called Ununpentium, “It has the unique quality of having an electric field greater than other elements.” In stable form it is a “powerful energy source”.

From another source, I read that the military has “at least 12 known advanced aerospace craft currently in use…” They may be using all 3 of these methods mentioned here – if they found them worthwhile – as well as others unmentioned.

This reminds me of a patent for an antigravity engine utilizing nuclear spin force, using a gyrating primary structure made of material with aligned spin nuclei, modulated by orthogonally rotating secondary members (also of aligned spin nuclei, but of course aligned with secondary rotation). This created a sine wave modulation of the spin interaction, which is anti-gravity.

sid briscoe

not likely, it sounds so different, however I found an article on the “Cook Inertial Propulsion Engine” (Robert L. Cook) which does sound similar.

Actually, it is hard to keep track of the many designs written about these days and maybe this is the second one you have read about. ok.

Some using electrical fields have interested me as well.

Hello! Where do I find such materials to make a Flying Machine and has to explain the functionality of the flying machine.

Tesla’s flying machine, page 1 … tells about the materials needed and explains how it works.

I feel like you went at this the wrong way and this is going to sound a little vague:

Teslas flying machine was based off of tesla coils. I swore it had something to do with a gyroscope like the ones you see in the M1A1 Abhram tanks (looks similar to a toy gyroscope) except you have four that are properly polarized electromagnets spinning at specific rotations together to create an X/Y/Z axis although I don’t remember what I thought one of the gyroscopes was specifically used for. The magnets are then charged individually for each axis to balance and compensate to create the desired direction of propulsion or stationary vector. You literally use Fundamental Forces you create from electromagnetism to push and pull you where you want to go. I couldn’t tell you the specifics although one of my instructors at my old A+P school does this for a living.

Though I’m glad someone is on the tesla flying machine project, ever since the U.S. government classified his documents and patients the night he died it would be awesome for some else to recreate it.

I recall reading that Tesla said the ideal shape for his flying vehicles would be cigar or saucer shaped, is that correct? If so isn’t it interesting that only less than a decade passed after his papers vanished that the first reports of “ufo’s” we’re of cigar and saucer shaped craft?

Hey nice build have u read any on frequency levitating like monks in Tibet if I had a guess I’d say the gears are gyros to keep the craft stable and the frequency they put off is the lift. think of a gyro it doesnt lift just stables but vibration is sound and I think he was going for the sound thy put off at a certain rpm but gl like ur craft

– Robert Combs

frequency levitation is a different but very interesting topic.

Finally I understand how the device works.

1) The gravity center of weights and device turn in circle ( this is very obvious).

2) The centripetal force does not exist because the frame is free to move.

3) Exist a vertical force on the x axis, the weights tend to tilt the frame, pivoting by GC lifting frame (and center of rotation)

3) The center of gravity is pulled in spiral path, due to buckling of the forces over frame.

4)Requires a high rate RPM to work. Thus the effect is manifested.

5)The device does not violate any physical laws, only brains.

Clearly, nothing about it is understood nor “obvious”.

-editor

I’m curious if you have done any experiments with this recently? The first time I saw Tesla’s “blueprint” for this engine it instantly made sense to me. For whatever odd reasons I’ve never made the time, money, or effort to build one for myself. I’d like to make a few suggestions that may help your machine work.

First of all, your moving diagram on page three is upside down. The eccentrics should be moving down towards the center according to Tesla’s diagram. ‘Push, not pull.’

Secondly, I’m not sure why you decided to have two arms on each eccentric (possibly to reduce warping of the axis?) I think you should return to the original design of one arm with a disc or sphere weight on the end of it.

Next, and I believe this is critical, the eccentrics need to be quite nearly half the length of the axis so that the mass of the eccentric is passing through the center of mass of the engine, “X.” It is, however, possible that they should be slightly shorter, as per the diagram.

Lastly, for now, it seems to me that Tesla was referencing using his steam/compressed air turbines that spun at 35,000 rpms to power this engine. Since I seem to have such a hard time finding out what is available along these lines, I had always envisioned using electric ‘4″ angle grinders,’ which spin at around 10,000rpm, geared out 1:4 so that the axes can spin up to 40,000rpm and then using a simple dimmer switch to control speed. Also, bearings and miter gears that can withstand that speed don’t seem to be easy to come by?

I hope my ideas and suggestions are clear and helpful. I sure would love to see this thing in action. I am a firm believer that it can work and would revolutionize the world.

Thanks for your time.

Maybe you will get a chance to build one and experiment. The metal is cheap. the motors, pillow blocks, and miter gears cost more but may be cheap enough. I went to 2 stores, Grainger and Kayman (Kayman Industrial Tech.) for the pillow blocks and gears.

However, the device is symmetrical. Right side up is exactly the same as upside down, and rotation has no “push” or “pull” it is “twist”: cw is the same as ccw. The center of mass of the eccentrics needs to be the same distance out from each axis and at the midpoint between the miter gears and they all need to weigh the same. The weight of the device and the radius and weight of the eccentrics affect the required rpm (and therefore, the power of the motors that will be needed). That’s it.

Have you tried just putting the device on a scale while it’s running? If it’s generating upward force, then it should get lighter, even if it doesn’t leave the ground…

If it gets (significantly) lighter, then you know you’re on to something. Otherwise, it’s just a waste of time.

Better, when the rpm’s got up higher, the vibrating did not smooth out when it should, it got more energetic. Even a mechanic who was observing said “something is going on”.

-ed.

Hint. Your view of weights opposing is skewed. Try one weight up one down as you have two of them but the other two need to either both pointing inward or both outward. True counters of one another as opposed to both swing weight the same direction at any point! Let me know how it changes.

do that and the center of gravity will just slide back and forth.

– editor

The problem is the frame if the machine works properly the outside will glow. The frame must be concentric within .010 of an inch. The box of steel is lined with copper. The copper lining creates an electrical attraction in conjunction with the magnetic pull of the eccentrics which generates a force field.The engines are magnetic based, very cheap to make. They are basically step motors magnetically driven and can achieve over 100,000 rpm. 7% cobalt carbide is also an option as drive shafts because magnetic fields flow around them and have no reaction. This was a little scatter brained but the theory is solid and the eccentrics must possess both equal and opposite weights. If you don’t get it once I have funding the world will change forever or I’ll get ripped apart. Good luck.

Almost forgot no outside sources of power are needed use magnetic fields to generate the electrical charge free and self sustaining for long periods of time. The stronger the field the higher the charge. If you can’t build a battery and fully understand circuitry don’t do this you will probably die.

Yes, the eccentrics do oppose or counterbalance each other – and that keeps the center of mass on a horizontal plane around the center point of the frame.

Other than that your declarations do not seem to relate to this device. It might clarify things to read the book Tesla, Man of Mystery (see pg.1) and see the original drawing to eliminate any misconceptions.

-ed