updated 08-02-2014

from Tesla’s Flying Machine, page 1

Tesla’s Flying Machine

Page 2

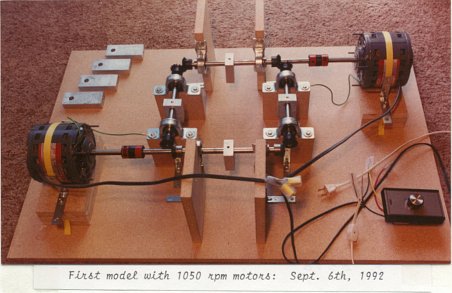

“Tesla’s Flying Stove”

“Not the airplane, the flying machine,” responded Dr. Tesla.

A few weeks later, I traded these motors for 10,000 rpm 1/5hp motors.

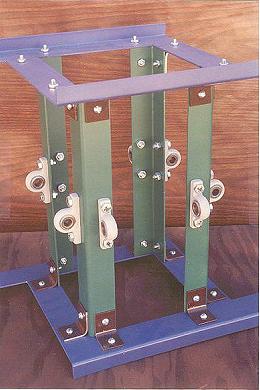

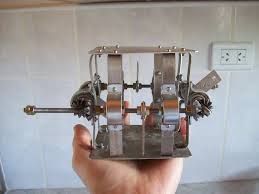

Second Tesla Space Drive Design

Since nothing is said about weight being an issue, my second

(all steel) frame was built to be rigid, not light-weight.

it was right after this that I figured out the speed

requirement and the variables that affect it

Third model, with 10,000 rpm ele. motors

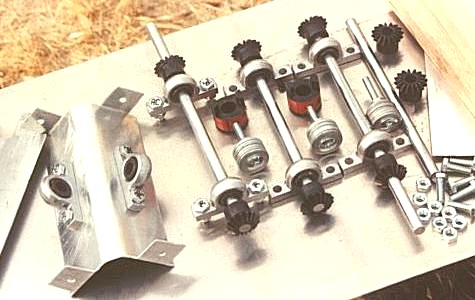

The only expensive parts are the motors, (aluminum) pillow blocks, and mitre gears.

The pillow blocks, and mitre gears, combined, totalled $138.44. About a 2 foot square sheet of aluminum was less than $10. The shafts are also aluminum and cheap.

The shafts and pillow blocks are also, now, aluminum alloy. This model was fine but, the frame was just a little flimsy.

Note: I used the red/orange (Lovejoy) jaw couplings because they were a cheap easy way to attach weights on a shaft. I just replaced the set-screws with bolts. For a good close-up, click on the photo above (the 3 photos) to see an enlargement.

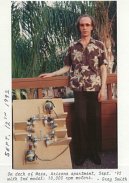

Experimenting out in the back yard, 1993

here I and a friend discovered the frame flexed a little

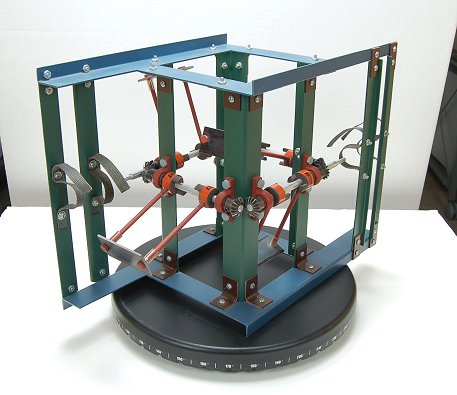

Final design: January 1994

using .090 inch aircraft aluminum ($9)

and 2 22,000rpm air motors ($50)

the frame is rigid and the motors are very light weight

I made the frame taller to accommodate longer arms and, slower speed requirements but, that was not necessary. However, there is an increased strength and reduced stress benefit to the double arms.

photographed on Fri., March 24th, 2006

Oct. 20th, 2007:

A few weeks ago +/- I tried it without any crossbars but, the weight and inertia were still too much for the motors. we got maybe 200 rpm but, we need maybe 600 to 800 rpm? I think the air pump where I am trying it, is not as strong as the one I used in Phoenix.

Nov. 2007:

I bought 2.5″ bolts and 1.5″ bolts so I have 2 more options. If the 2.5″ does not reduce the weight and inertia enough to enable the motors to get up some significant speed, I can try the 1.5″ bolts.

Cutting the length, and weight, in about half (from 4.75″ to 2.5″ bolts) reduces our net radius from about .1″ to about .025″ and our needed speed from about 600+ rpm to about 1200 rpm. Although it was an improvement, It just was not enough improvement and we switched to the 1.5 inchers. (see “December 2007” photo below) We started it up and the speed finally seemed significantly improved. A mechanic said it looked like it was going about 5 or 6,000 rpm. Great! Finally! Still, nothing more happened and we turned it off.

(we have no way of confirming how fast it was going – I think maybe only 1 or 2,000 rpm)

December 2007

Afterwards, I realized several potential problems. (1. The force may have been exerted downward instead of up (we need to try turning it upside down) and, (2. the 2 air hoses were adding weight to the system, holding it down. We need to prop the hoses up so that they do not add weight to the system.

Jan. 30th 2008:

We tried it again, right side up and upside down. We held up the 2 air hoses. But, no movement, no lift. It may be that we need 3-4000 rpm but are only getting 1 or 2000.

Testing at an auto body shop, Jan 30th 2008

|

|

June 30th 2008

If we got several thousand rpm, enough(?), then, it didn’t work. If not, then either a further reduction in the mass and inertia of the rotating weights and / or a change to stronger motors is needed.

Hopefully, we can get a sufficient speed increase by further reducing the weights & inertia. If not that, then by getting the weight of the motors off the frame by using couplers to extend the 2 shafts out beyond the frame.

March, 2009

I started getting calls from a TV production co. in Calif. wanting to put my flying machine on a Discovery Channel special.

I stopped at the auto shop, told them about it. They told me that they have gotten a new, stronger, compressor. Now is the time to try again!

Saturday, March 21st, 2009

Saturday was a disappointment. The new compressor provided significantly more power than the old one. The speed was much improved, very impressive, “more than enough”. This time I do think it was up to 3 or 4000 rpm, if not more. However, the weather was bad, raining, and I only did half the test. Still, it did not move. There was plenty of speed in the rotating masses. So, either I had it upside down, 50-50 chance of that being true, since it is totally symmetrical, or there is some stumbling block, some criteria I have not thought of.

Wednesday, July 22nd, 2009, 9am

Tried it again. The speed, again, seemed enough. But, again, I can’t be sure, and it did not go up.

2011, Footnote:

A frame is cheap, a person can design and build one around motors they come up with, the smaller the better, perhaps. Smaller motors can generally run at higher speeds. Extension rods, longer rods, can be used to get the motors off the system, and that will reduce the total weight greatly.

Here is one Marcelo B. built. Glad to hear from him.

back to Tesla’s Flying Machine, page 1

I’m so glad to see that your website is still up and running here. It has taken me many years to figure out exactly what is going on with this invention. although this invention was never meant to provide lift, it is however no less absolutely one of Tesla’s great inventions. this device was meant to be put into one of Tesla’s flying machines and should have been called the Tesla Non-Gyroscopic stabilizer.

Traditionally gyroscopes were used for navigation often they were used in pairs spinning in counter direction to each other to form a point of reference to navigate by. Gyroscopes have an inherent problem with Gyroscopic precession which requires a set of gimbals to correct for. Lastly gyroscopes are not used to directly stabilize a craft because of those physically inherit problems.

This device when running should create an horizontal X/Y plane of inertia that with the proper size weights and properly attached to the frame of a craft should create a stable platform that would resist pitch and roll tendencies from a free floating plane. Leaving free to travel in the Z axis (UP, Down) or forward and backward by some other force. Think how easy this would make flying for the average person. This might be a good device to try on a drone quad-copter if you wanted it only to travel straight up and down.

Lastly through my studies, I believe Tesla knew how to levitate heavy objects through the use of high static electric potentials. But would require more insight and information than I’m prepared to discuss right now.

I would like to get in on this iv allways been interested in all Tesla’s inventions

USe a tesla turbine

And use alternating polarity magnets as weights?

try it with the weighing instrument. Maybe it’s just reducing gravity

hello it’s so interesting thing,, althought it can’t lift up, i suggest that it function is something like stabilizer or gyroscope,,, it will make everything which bond with it, will not going diagonally, always remain horizontal,,

Then there’s something wrong with the diagram. I saw and downloaded a while ago. It’s odd the video disappeared off my tablet. but they had a working model. Unless it was fake. the weights were started not in line, staggered.

Great to see it build but it’s obvious it’ll never work this way.

Tesla’s Physics instructor told him AC motors were impossible also.

It looks apparent you forgot to spin the whole machine in synchronization with the positions of the masses. So the net effect can be a unidirectional force. The vectors have to add at the right time, and cancel elsewhere. Without the spinning ( horizontal plane ) with respect to the ground, the thing will likely just vibrate. Forget all the mumbo jumbo, this is simply vector addition and timing. For a good demo concept have a look at “solid mass centrifugal propulsion” by the ISA on youtube. I also have a channel called centrinamics systems with some videos of my experiments so far. Excellent efforts by the way!

If anyone is interested, here is my design of the Tesla stove.

http://overunity.com/17424/tesla-stove/

very impressive. You actually built it! Great!

Note: don’t forget, using only one motor throws off the center of gravity.

and, the heavier the frame and motor, the faster, heavier, the “eccentric” weights need to be.

Ya, actually a second motor could be used with and second Tesla stove assembly, that would be geared with the first so that it would counter act the 90 degree force that occurs when the loads are not pointing up.

The weight of the frame is not my concern because what this represents is a “proof of concept” only. If force can be measured by using the vertical pendulum test or observe a change in weight, then I believe that an increase in funds would be used to create a more efficient, aluminum type frame that could withstand high load capabilities and higher rpm.

After reviewing the equation for centripetal force that assumes a uniform circular path:

Force = mass x radius x (2 x pie x frequency)^2

And that this really can be broken down into two parts…

the first is the outer radius and the second is the load radius. Referring to the equation above, the centripetal force holding the load on the outer radius, at the bottom of the stroke, will always be greater than the centripetal force of the load radius if the load radius is shorter than the outer radius.

I am working to design a split longer load to pass the main axle so that the load radius is longer than the outer radius, as well as concentrating the load at the very end. It’s going to be awhile, 3D printing takes time, and I’m not completely sure on the best design to do it. Thanks for taking a look, and if anyone would like to correspond with me on this project, please feel free to post on the website that I posted my project on. :)

http://overunity.com/17424/tesla-stove/

keep up the good work!

Know ur into tesla but, please think about hydrogen atoms and air intake……within ur spinning motion… U have the hands to build…the atom is answer…please…am not kidding…..use ur skill…it’s been done for longer than u know .

why not spin electro magnetic fields instead of mass

How about some magnets on the eccentrics?

Research also in this way since 1995. I resumed research this year. Sorry for my English. I believe that this machine works on the same principles that I imagine is the balancing of centrifugal force in one direction. How is its prototype, the centrifugal force is in all directions. You doesn’t targeting the centrifugal force. I always speak centrifugal force because i dont believe in the existence of centripetal force. This force is confused with other well known forces such as friction in the tires of a car when it makes a turn.

so does it work?

The eccentrics need to be strong magnets, in the shape Tesla drew, with the striped part (as seen in the drawing) being the positive end, exactly as he positioned them.

Lol! You fools! He was trying to get employed after Thomas Edison ripped him off, cheated him, and put a bad word out to keep him from becoming a successful business rival! Westinghouse cheated him also, the man not the company for he cheated him out of millions! He left out important aspects of the equations and plans so that they would have to hire him to make it work! They didn’t bite because Tesla was way too far ahead of his time for the times! His ideas scared people especially business people who were making millions with the current technology and Tesla’s improvements and new innovations would have forced them to have to change, catch up, or put them out of business.

I think he let Otis t Carr take over on this they were good friends

U.S. Patent 7900874 gives you info on this.

If any one wants more info of the unit I saw email me I have limited internet.

( edhillman62 .at. gmail.com )

Hi, what is your email address?

The unit I saw was metal frame cube power was 2500 rpm 5 lb brass weights pie shaped one engine to power two weights equal one piston of the engine