posted Oct. 9, 2010

updated Dec. 9, 2015

EcoMotors Establishes R&D Center with Hunan University to Develop opoc Technology in China

Fri, 03/14/2014

Allen Park, Mich., March 13, 2014 – EcoMotors, Inc., (EM), developer of the efficient, clean, lightweight and powerful opposed-piston opposed-cylinder (opoc®) engine technology, announced today that it has established a joint research and development center together with Hunan University (HNU) in Changsha to further develop and adapt their technology for the Chinese market.

The new center will be located at HNU’s Research Center for Advanced Powertrain Technology (RCAPT) and serve as a base for EM research and development in China. EM will provide funding to develop opoc engines and associated technologies, and adapt them to the local market. For its part, HNU will give EM use of the RCAPT’s engine testing and computational facilities, as well as other resources.

“As our first overseas R&D center, this partnership is an important step in the commercialization of our advanced technology and a sign of the importance this market plays in our global strategy.” said Amit Soman, EM’s president and chief operating officer. “At this center we will fine-tune products to meet the specific needs of the Chinese market and provide support for our other partners in China.”

Located in a province that serves as an industrial base for mechanical manufacturing, the center also will provide EM with access to top local talent. As part of the partnership, EM will give scholarships to graduate students at HNU’s research center, funding their work on the opoc technology. The most promising students will be sent to work at EM’s Shanghai office or other EM facilities.

. . .

from http://www.ecomotors.com/post/ecomotors-establishes-rd-center-hunan-university-develop-opoc-technology-china

EcoMotors Quickens Its Pace, Acquires Michigan-Based Katech Manufacturing

Wed, 03/12/2014

Allen Park, Mich., March 12, 2014 – EcoMotors, Inc., (EM) announced today the purchase of Katech, Inc., the Michigan-based manufacturing company known for developing advanced engines and powertrains, adding additional expertise, manufacturing and testing capabilities to an already growing company.

. . .

Katech has developed and produced technology for multiple automakers, including General Motors, Ford and Chrysler. Katech engines have also powered the famous GM Corvette Racing team that has dominated the U.S., and global GT racing circuits by capturing six championships and winning the legendary 24 Hours of LeMans six times.

Engine Production Expected To Begin In 2014 [2015?]

$200 Million Deal to Build OPOC Engine Plant

Xuancheng, Anhui, China and Allen Park, Michigan, April 9, 2013

Zhongding Power and EcoMotors today announced the closing of a commercial agreement to produce the opoc engine, a breakthrough technology that has the potential to be the world’s cleanest, most efficient, lightweight, and lowest cost internal combustion engine. One of the largest automotive component conglomerates in China, Zhongding will finance and construct the first opoc plant in the Anhui Province. The plant represents an investment by Zhongding of over US $200 million and will have a capacity of about 150,000 engines per year – over US $1 billion in revenue potential. High-volume production is expected to begin in 2014.The opoc engine technology developed and owned by EcoMotors can deliver the same power level as conventional engines at half the size, a lower cost, and lower emissions. With the potential for 20-50% better fuel economy compared to a state-of-the-art, conventional turbo-diesel engine, EcoMotors’ opoc engine has the potential to revolutionize the internal combustion engine.

The inaugural opoc plant has received the full support of key Chinese government bodies, including the Xuangcheng government and Anhui provincial authorities; a second Zhongding production site may be announced at a later date. Zhongding plans to supply opoc engines to a broad range of customers, including GenSet engines, off-road and commercial vehicles. A key provision of the agreement allocates a portion of the plant’s output to EcoMotors for sale and distribution to its own direct customers.full article at http://www.ecomotors.com/zhongding-power-signs-strategic-agreement-ecomotors-fund-construction-200-million-opoc%C2%AE-engine-plant

June 16th, 2011

EcoMotors struck a parntership with Generac (NYSE: GNRC) this week to jointly develop fuel-efficient, backup power generators.

“We’re going to work with Generac to qualify the EcoMotors opoc engine for applications in gen sets, or the power generation area. We’d expect to begin to see [generators equipped with our engines] on the market in 2013. We have engines in prototypes, now in a wide variety of applications.

EcoMotors claims its opoc engines are 15 to 50 percent more fuel efficient than traditional internal combustion engines, as well as smaller and lighter

March 9, 2011, Cambridge Energy Research Associates (CERA) named EcoMotors “Energy Innovation Pioneer”

Oct. 23, 2010

OPOC: Opposed Pistons, Opposed Cylinders

Bill Gates and fellow billionaire Vinod Khosla announced that they were investing $23 million in EcoMotors, a Michigan company that has promised to produce an engine that would convert far more of its fuel energy into useful work, and in doing so crack 100 mpg.

Oct. 22, 2010; Esquire Car Awards: Innovation of the Year: The OPOC Two-Stroke Engine

In its key operating range, a diesel OPOC could convert as much as 48 percent of its fuel’s energy into work, beating today’s best diesels. Moreover, an OPOC engine is just half the size and weight of a comparably powered conventional engine, which reduces the burden of moving its own mass.

ECOMOTORS SAYS ITS OPOC ENGINE COULD DELIVER ABOUT 45% GREATER FUEL EFFICIENCY

EcoMotors is developing engines that combine two OPOC “modules”-the two-cylinder, four-piston machine shown here. Under light loads, one module would shut down for a 30 percent boost in mileage. Former GM chief engineer and EcoMotors co-founder Don Runkle says that next year the company will publicly demonstrate a 300-horsepower OPOC diesel, but not necessarily in a car. Automakers aren’t the only potential customers: Earlier this year, Eurocopter unveiled a concept helicopter powered by two OPOCs. – Lawrence Ulric

The Defense Advanced Research Projects Agency (DARPA) originally sponsored OPOC as a powerplant for the A160 Hummingbird UAV, but went with a turbine engine as a lower-risk solution for current test flights. However, L-3 reports strong interest from the UAV community both in the 325 hp M100 – which can be assembled into four-cylinder, 650 hp and six-cylinder, 975 hp configurations – and the small 85 cc, 10 hp S30 for mini-UAVs.

EcoMotors

named 2011 Energy Innovation Pioneer by IHS Cambridge Energy Research Associates (CERA)

Allen Park, Michigan, March 9, 2011

In conjunction with the CERAWeek 2011 conference in Houston, EcoMotors has been named as a 2011 Energy Innovation Pioneer. IHS CERA annually selects innovators based on their potential as game changers or drivers of improvements in existing systems. CERAWeek 2011, highlighted by addresses from former presidents George W. Bush and Bill Clinton, among others, is dedicated to providing insight into the future of the global energy industry and to impacting decisions and policymaking.

“We are very proud to have been named as an Energy Innovation Pioneer and to participate in the CERAWeek 2011 forum,” said Don Runkle, CEO of EcoMotors. “This recognition not only underscores the revolutionary nature of our opoc engine, but also reflects our increasing momentum as OEMs like Navistar partner with us to commercialize this remarkable technology.”

EcoMotors a Finalist in Auto News’ PACE Awards

Allen Park, Mich., November 24, 2010 – EcoMotors opoc engine is a Finalist for the prestigious – Automotive News’ PACE award. The PACE (Premier Automotive Suppliers’ Contribution to Excellence) awards are selected annually from among the automotive supplier community and recognize practical innovation in the automotive marketplace.

This year thirty-five innovations qualified as finalists for the PACE Awards. EcoMotors opoc is the first and only new engine architecture to be a finalist in the history of the PACE Awards…a remarkable achievement.

“We’re very proud to be a finalist for the PACE awards,” said Don Runkle, CEO of EcoMotors “but we are not surprised, the awards recognize practical innovation and that is one of the defining characteristics of our engine.”

Established in early 2008, EcoMotors is quickly achieving critical mass in terms of changing the landscape of internal combustion power. Based in Allen Park, Mich., EcoMotors is commercializing the unique opoc engine for use in cars, light trucks, commercial vehicles, aerospace, marine, agriculture, auxiliary power units, generators, etc. Anywhere conventional gas or diesel power is currently utilized, opoc represents a better propulsion solution.

The two primary investors in EcoMotors are Khosla Ventures and Bill Gates. Khosla Ventures offers venture assistance, strategic advice and capital to entrepreneurs. The firm helps entrepreneurs extend the potential

of their ideas in breakthrough scientific work in clean technology areas such as solar, battery, high efficiency engines, lighting, greener materials like cement, glass and bio-refineries for energy and bio-plastics, and other environmentally friendly technologies as well as traditional venture areas like the Internet, computing, mobile and silicon technology arenas. Vinod Khosla founded the firm in 2004 and was formerly a General Partner at Kleiner Perkins and founder of Sun Microsystems. Khosla Ventures is based in Menlo Park, California.

Bill Gates, Vinod Khosla invest in low-cost, low-emission automotive engine

19 July 2010 , Written by Dhruv Tanwar

EcoMotors has secured “Series B” funding from two of the most prominent investors it could find, Microsoft Chairman Bill Gates and Vinod Khosla of Khosla Ventures and the co-founder of Sun Microsystems, a company acquired recently by Oracle. News reports pegged the amount funded at $23.5 million, though EcoMotors did not comment on the value.

EcoMotors International CEO Don Runkle announced that his company has secured substantial Series B funding, which would be sufficient to complete engineering and testing of the Opposed-Piston Opposed-Cylinder, or OPOC engine. The company said Khosla and Gates invested in the company sharing the belief in the global potential of the opoc technology and its potential disruptive impact on modern transportation emissions because of its cost effectiveness.

This design configuration eliminates the cylinder-head and valve-train components of conventional engines, offering an efficient, compact and simple core engine structure, resulting in a type of engine that is lighter, more efficient and economical, with lower exhaust emissions compared with conventional designs.

the EM100 diesel model, which has a cylinder bore size of 100mm and weighs 134 kilogrammes, it is capable of producing 325hp at 3500rpm along with an incredible 900Nm of torque.

Esquire magazine

After six months of testing, we present this year’s winner – and some very honorable mentions. By Sam Smith

EcoMotors CEO Don Runkle hauls around America … a forty-pound motor that generates up to ten thousand kilowatts of energy. That’s enough to power a home, on a fraction of the fuel that a typical engine would need. Enough to convince many executives that the Engine That Changes Everything may have finally arrived.

Where typical engines have one piston per cylinder, hammering up and down like a fist against a ceiling, the OPOC – which was designed by a former chief powertrain engineer at Volkswagen – has two pistons per cylinder that come together and pull apart like hands clapping. The pistons travel only half as far, meaning they can complete a cycle twice as fast, which lets OPOC generate twice the power of an equivalent standard engine – the same power in a package half the size. Further innovations in fuel delivery and exhaust and the innate efficiency advantages of the two-stroke cycle mean the system offers, conservatively, 50 percent reduction in fuel usage with no reduction in power, no increase in emissions, weight savings of 50 percent, and cost savings of 20 percent.

Aviation company Eurocopter is pursuing a diesel version that would be the most fuel-efficient helicopter engine ever.

WARRENVILLE, Ill., Feb. 22, 2011 /PRNewswire/

development agreement between EcoMotors and International brand commercial and military trucks, MaxxForce brand diesel engines, IC Bus brand school and commercial buses, and Monaco RV brands of recreational vehicles.

Navistar Continues to Deliver Customer-Focused Solutions by Working with EcoMotors to Commercialize this Innovative, Cutting-Edge Powertrain

About Navistar

Navistar International Corporation (NYSE: NAV) is a holding company whose subsidiaries and affiliates produce International brand commercial and military trucks, MaxxForce brand diesel engines, IC Bus brand school and commercial buses, Monaco RV brands of recreational vehicles, and Workhorse brand chassis for motor homes and step vans. The company also provides truck and diesel engine service parts. Another affiliate offers financing services. Additional information is available at www.Navistar.com/newsroom.

WARRENVILLE, Ill., Feb. 22, 2011 /PRNewswire/ — Navistar International Corporation (NYSE: NAV) today announced it has reached a development agreement with EcoMotors International in support of the company’s opoc (Opposed-Piston, Opposed-Cylinder) engine architecture.

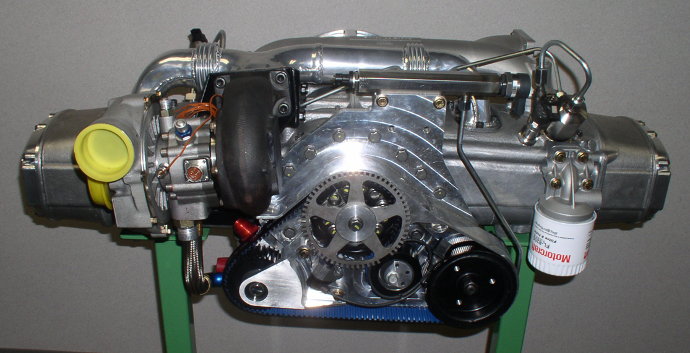

EcoMotors International’s first product targeted for commercial application is a turbo-diesel version of the innovative opposed-piston, opposed-cylinder engine.

“We continue to be on the cutting edge of technology and our development agreement with EcoMotors once again demonstrates our commitment to develop new, innovative approaches to the commercial vehicle industry,” said Dan Ustian, Navistar chairman, president and chief executive officer. “Our company has a long history of pushing the envelope to deliver state-of-the-art, customer-focused solutions and we see great promise in EcoMotors’ breakthrough engine design.”

Khosla Ventures’ Vinod Khosla, EcoMotors’ primary investor along with Bill Gates, sees the Navistar-EcoMotors alliance as a reflection of the disruptive nature of the opoc technology.

“We are delighted that Navistar, a global leader in the commercial vehicle industry, has recognized the game-changing promise of opoc,” said Khosla. “The only truly disruptive technologies are those that can provide not only rapid payback but also economic and carbon benefits to large segments of the world’s population without the need for subsidies or massive infrastructure investments. Among next-generation propulsion systems, the opoc engine is broadly applicable and can provide lower carbon emissions than almost any other technology.”

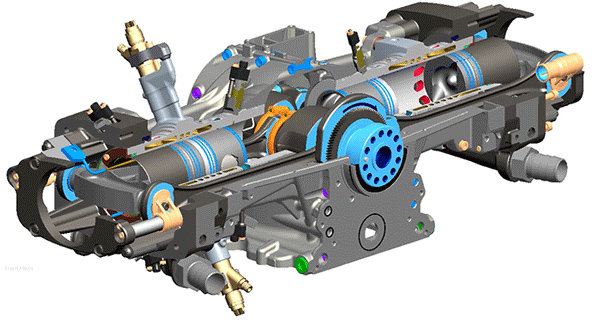

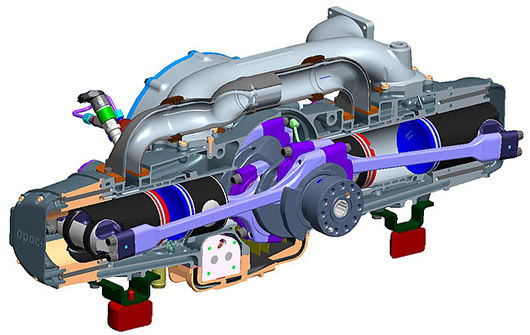

Opposed-Piston, Opposed-Cylinder Engine with Modular Displacement Capability

EcoMotors’ patented engine design creates a ground-breaking internal combustion engine family architecture that will operate on a number of different fuels, including gasoline, diesel, natural gas and ethanol. The opoc’s new opposed piston-opposed cylinder direct gas exchange operation provides the well known emissions benefits of 4-cycle engines, the simplicity benefits of 2-cycle engines, the power density of the less well known opposed piston engine, and the extraordinary developments in electronics and combustion technology all tied together in a new and proprietary engine architecture.

“EcoMotors is proud to partner with Navistar to commercialize the revolutionary opoc engine,” said Don Runkle, CEO, EcoMotors International. “For customers such as Navistar, this remarkable engine technology represents a competitive advantage that enables not only enhanced environmental sustainability, but also greater profitability. Our engineers are working to effectively rejuvenate the internal combustion engine for the 21st century.”

The opoc engine comprises two opposing cylinders per module, with a crankshaft between them — each cylinder has two pistons moving in opposite directions. This innovative design configuration eliminates the cylinder-head and valve-train components of conventional engines, offering an efficient, compact and simple core engine structure. The result is an engine family that is lighter, more efficient and economical, with lower exhaust emissions.

EcoMotors’ opoc engine has a number of distinct advantages over traditional internal combustion engines. The opoc engine has very high power density of nearly one horsepower per pound resulting in an unprecedented lightweight and compact engine. The opoc engine is perfectly balanced enabling stackable power modules. This unique modular displacement capability is one of the long standing, but elusive goals of engine engineers’ quest for high efficiency. In addition, it also results in much less NVH than a conventional engine of comparable power. Its elegantly simple design allows for low cost, efficient manufacturing and increased operating durability:

50 percent fewer parts than a conventional engine

Straightforward assembly

No cylinder heads or valve-train

Uses conventional components, materials and processes

“Consistent with our leadership strategy, Navistar continues to seek innovative products which differentiate us from the marketplace, while others embrace the status quo,” said Eric Tech, president, Navistar Engine Group.

Power Density

The internal combustion piston engine has been the primary means of automotive propulsion for more than a century. Today, thousands of engineers around the world are hard at work trying to improve this 19th century invention. Some are striving to make incremental gains; some are hoping for a breakthrough. For all of them, one measuring stick is the “acid test” for any engine — power density. As greater power density is achieved, a range of critically important attributes will result, including:

Lower weight

Smaller size

Lower material costs

Lower friction

Greater fuel efficiency

Lower emissions

Lower heat rejection

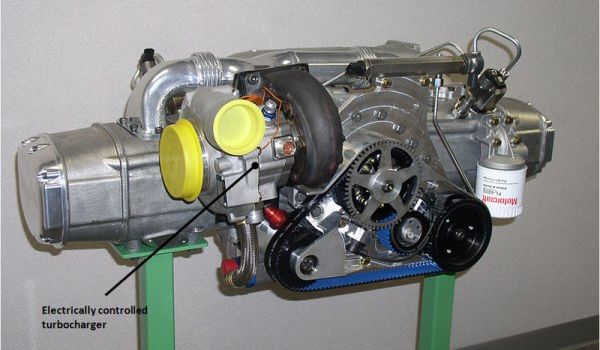

Electrically Controlled Turbocharger

EcoMotors’ intellectual property also includes an electrically controlled turbocharger technology which incorporates an electric motor in the turbo assembly to regulate boost pressure resulting in a long list of unique advantages:

Improved combustion efficiency to meet emissions

Electrically controlled variable compression ratio

Improved vehicle fuel economy

Enhanced vehicle drivability due to improved low-end torque

Eliminates Turbo lag

Waste heat recovery by generating electricity

Electrically Controlled Clutch

The development in clutch technology enables customers to take advantage of the engine’s modular displacement capability. The clutch assembly is housed between two engine modules, and is engaged when vehicle power demands require both modules to deliver power. When the power of the second module is not needed, the clutch is disengaged, allowing the second engine to stop completely. This not only improves fuel economy dramatically by reducing parasitic losses, but also improves the efficiency of the primary module.

About EcoMotors International

Established in early 2008, EcoMotors is changing the landscape of internal combustion power. Based in Allen Park, Mich., EcoMotors is commercializing the unique opoc engine for use in cars, light trucks, commercial vehicles, aerospace, marine, agriculture, auxiliary power units, generators, etc. Anywhere conventional gas or diesel power is currently utilized, opoc represents a better propulsion solution. The two primary investors in EcoMotors are Khosla Ventures and Bill Gates. Khosla Ventures offers venture assistance, strategic advice and capital to entrepreneurs. The firm helps entrepreneurs extend the potential of their ideas in breakthrough scientific work in clean technology areas such as solar, battery, high efficiency engines, lighting, greener materials like cement, glass and bio-refineries for energy and bio-plastics, and other environmentally friendly technologies as well as traditional venture areas like the Internet, computing, mobile and silicon technology arenas. Vinod Khosla founded the firm in 2004 and was formerly a General Partner at Kleiner Perkins and founder of Sun Microsystems. Khosla Ventures is based in Menlo Park, California.

for latest news see

EcoMotors.com/news

Read about a guy today who has his car, motorcycle, riding lawmower, and generator running on vapors-fumes:

Car gets 400+ MPG

For detailed instructions on making your fuel injected vehicle extremely fuel efficient ( to run on vapors ) bypassing fuel injectors and carburetors, see our page

Run Your Car On Vapors

1-1/2 inch diam. in-line valve for $15

the T fitting: 1-1/2 inch diam. = $3

1-1/2 inch diam. vinyl tubing = $3/ft

The first OPOC ?

The Bourke Engine

Invented by Russell Bourke in the 1920’s, one test model was 38 pounds, 30 cubic inches, 35 hp or more at 5,000 RPM, 76 hp at 10,000 rpm; successfully tested up to 20,000 rpm; Estimated up to 5 HP per cubic inch with Compression ratio up to 20:1; Fuel air ratio: 30:1 to 50:1

This EM-100 motor combined with the ZF9 transmission. I would very much like to see this in GMC Passenger van I would buy

two.

Ummm im confused ! Isn’t this just a . . . flat four cut in half ? This is being hailed as brillant ? The first opposing cylinder engines were made back 1933 . . .

cut in half? not hardly. It is doubled in length with 4 pistons in-line. Awkard. A mess compared to the Bourke in the 1920’s. Do a google search on the history of the I.C.E. There is a lot to learn. What this has going for it is 2 millionaires – a little harder to intimidate and threaten into submission.

I like ur project. I am also on the way to make $1000.00 one thousand dollar car this year. Pls check this video taichi engine in youtube. There may be business challenge between us pls check it. I like your visitors display its lovely designed. Regards

Nepal alternative power resources p ltd

*alternative access to scientific arts*

for the original design, see The Bourke Engine

stupid if we all get electric cars what happens when we a blackout in the western usa have a snow storm in the east usa and and have a black out at the same time the democrats will want more taxs I hop you are on to something BIG

howard edwards

this has nothing to do with electric cars. The question is, can the oil co.’s stop the two millionaires who are funding this as they have stopped all other attempts to cut our dependence on oil.

To George McGinnis [comment below],

If this is available then why don’t we find this on the market. I sure would like to try any type of product that would give me mileage and be cheaper. I drive an average of 250 miles a day 7 day week. let us know.

Pete Schmidt

Since George never said any more about it unfortunately, we can only guess that he did not do any more about it. But, for everyone who seriously wants extremely high gas mileage today, not tomorrow after tomorrow, they can now read our new page “Run Your Car On Vapors” mentioned above and do something about it. … We could suggest it to him also. [done]

Evinrude Outboards , Has the first 2 cycle , computer controlled, but ECO motor, is even more efficient. See you tube , Evinrude Etec, full version. to see the first computer controlled 2 cycle. I work @ Evinrude for 30 years, now BRP.

Tom Wrona

yes, and vaporizing the fuel makes any vehicle about 10 times(+) more efficient yet. See our “Run Your Car on Vapors” page.

http://fuel-efficient-vehicles.org/energy-news/?page_id=968 will tell you about the AVFS and/or you can just type into any search engine John Weston AVFS and find that there is still another way to help reduce the number of gallons of fuel and the reduction in emission. Will EcoMotors be interested in contacting me, John Weston, about applying the AVFS to the OPOC engine? My intention for presenting the AVFS to the market initially is also for operating internal combustion engines on generators, for the sake of NOT being limited to the “grid” for energy that is needed.

John Weston

AVFSman@aol.com

765 377-0628

THANK YOU FOR YOUR RESPONSE…………

When will you have a marine engine available for purchase, and what will it be? I am interested in two twin engines for a sport fishing yacht in the 35′ to 38′ size. What kind of performance would you expect?

Thank you

Lillian Feingold

very good invention keep up the good work – junior gaynor

I have an engine that increases the m/g, horse power, and decreases emissions. All by at least 50%. where do I get help? All for the cost of about $50.00

george mcginnis

2014/04/28

George, when you wrote back in October [10/21/2013] there was nothing to say.

Today, we have great videos, pictures, a drawing and experimental instructions-documentation of people freely sharing how to get 500% to 1000% better gas mileage – all for about the same $50 or less in parts. See our “Run Your Car On Vapors” page – mentioned above.

I could use one of these engines in my PT Cruiser instead of the V-piston and outrageous sensors on it. I would my much H P and and supr MPG than my 2.4 eng. I’m all for better than car companies old age technology being lazy and reforming for the betterment. Try to make a opoc that I can bolt into my PT CRuiser.

These v cam gas shaft engines are a waist. If I had the machinery I would build one my self. If you want to put one of these in my PT Cruiser to test just e-mail me and I will meet with you. I am 70 yrs old.

John bender

I see 2 problomes here.

number one it depends on forced enduction to run. not as a power adder but to function without a valve train it has to have compressed air. it seems to use a turbo for this. but niether turbo or superchargers can provide boost untill the engin is runing. so you need another engine to start this engine but after that it should work,

and it looks like it’s going to have oil consumption issues to. probbly 3 or 4 qwats a week. if it’s ussed in my car the way i drive.

before this can work you need a few things. the case is all wrong youll never get it to stop over heating in that.

I could make it work. if i had the time an money. I don’t think there even close to figureing this out. i think there just trying to get pepole to invest money. to bad because I love the idea of no vavle train. and no outer craink.simple. it would be so good for burning gas. maybe better on alcohol or propain but it’s not going to make it as a heat engine.

“It is our goal to manufacture and market the best internal combustion engine the world has ever seen.”

That’s what the guys are saying who claim they want to take the engine further. How come no one else picked up where the inventor left off decades ago?

you mean the Bourke engine? Good question.

Respectfully, where the hell are these guys getting their ridiculous numbers from? Claiming an efficiency increase from 20-50% over that of an existing diesel engine is profoundly insane for this OPOC design.

Less friction? I doubt it. They must be running at extremely low bmep’s and rpm’s too. I figure around 2.6% better efficiency at most. Also the engine is stupidly long for, say, auto installations.

I guess it will be ok in large sizes for stationary or marine applications.

Using the raw data from a competitor of theirs, namely Achates Power, I see nothing great coming from this design.

What about wear of the rings?, a unsolved problem nobody says

Wake up and read these articles.

The reason they went to China was MONEY SAVED and MONEY INVESTED. How much did CHINA invest? How much did the United States of America TAX, MANDATE, CONTROL and CHOKE the OPOC and EcoMotors companies?

Answer to my question #1: China invested MORE THAN $200,000,000.00 and there were very few Governmental Hinderances.

Answer to my question #2: I.R.S., E.P.A., O.S.H.A., MORE THAN 5 Building Permit and at least $28,000.00 REQUIREMENTS in Fees and Taxes, BEFORE any building could be started. Property aquisition expenses, planning expenses, development expenses, architectural engineering expenses, legal gladiator expenses, building proposal expenses and fees, impact fees, building permit fees (City, County and State) etc. Then the building MAY begin. Of course there would be Federal Government requirements, taxes and fees like ObamaCare, Equal Oportunity Employer, etc…etc…etc.

I do not speak Mandrin Chinese yet, but unless we flush some of the stink I will have to learn it.

Steven George

Most of our “American” branded drugs and clothes are being made in China. “The Asia-Pacific’s share of the worldwide semiconductor market is expected to continue rising at a rapid rate.” Most of our electronics have been coming from Japan for a long time. If you didn’t learn Japanese a long time ago, you can forget about learning Chinese … etc..

They don’t want to build it here but I’ll bet they want to sell it here and so it goes America just keeps getting poorer and China keeps getting richer

The OPOC engine is to be built in China. The plant is being designed to build the engine right now. The plant will build a max of 150,000 engines per year – not car production levels. The initial batches will most probably be for Generac generators.

thank you, we have referenced the opoc news release above

Dear Mesdames and Sirs,

I first heard about the OPOC engine several years ago from my father after he read about it online in automotive news. The reason for my correspondence is simple, and I only have one question. If this engine/technology is so immensely superior in every way possible to every other engine on the planet: why isn’t this technology in use right now in tens of millions of cars all over the world??

… because the oil companies do not want it produced!!

respectfully, Adam L. Adair MSgt, USAF, (Retired)

It is good, but It isn’t the best.

However, it does seem to be on schedule for production.

-ed.

The bourke design seems to be simpler and have fewer moving parts. Which would make it cheaper to build and sealing the crankshaft would mean very few oil changes. Also it would be able to run on various low octane fuels. This also is a 2 stoke which would not burn oil but only use oil to lubricate the piston. It looks to be easily balanced also. Correct me if I’m wrong.

We agree.